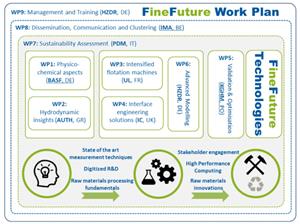

Department of Mineral Processing Engineering started an EU-funded project focusing on Fine Future Innovative Technologies and Concepts for Flotation of Very Fine Grains.

Flotation is one of the most important processes in the evaluation of fine sized ores today, which is made by taking advantage of the differences in the wettability degrees of the main materials. There are a limited number of studies for this process, which has been done in the past in relatively large size liberation sizes, with gradually decreasing liberation sizes below 20 microns.

The “Fine Future” project, funded by the European Union, will lead to the development of flotation recovery solutions for these fine particles and aims to provide important findings both in explaining the mechanisms and in the development of industrial applications. As a matter of fact, this situation will increase energy efficiency not only in terms of the evaluation of new critical raw material deposits, but also by re-evaluating the fine-sized wastes released in existing facilities.

In this context, it is very important to evaluate many mineral resources such as nickel, kaolin, feldspar, talc and magnesite in very fine dimensions and will help to secure both the global sales of European companies and the production of critical raw materials in Europe. Accordingly, the lack of critical raw material supply will hinder economic growth in rapidly developing industrial areas such as energy storage systems and industrial robotics.

Within the scope of the Fine Future project, it is aimed to eliminate this important gap mentioned above through the joint work of large teams consisting of different universities and industrial partners. In experimental studies, the properties of frothers, which are one of the most important inputs of flotation processes, are investigated in detail, as well as changes in viscosity values that will occur during flotation in the presence of these chemicals. The expected results from this project, which consists of different work packages, will offer new perspectives on the reduction of resource loss, the use of new resources and the recovery of fine grains by flotation through much higher energy efficiency.