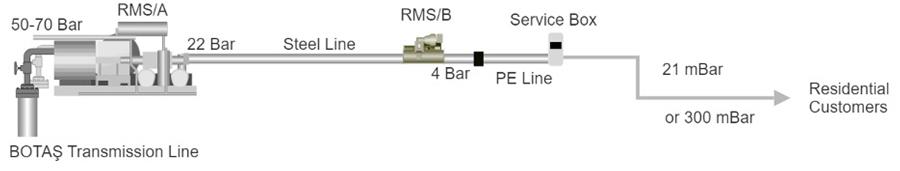

Through the BOTAŞ transmission line, natural gas reaches the local gas utility İGDAŞ at primary pressure-reducing and metering stations (RMS/A). The gas is distributed from RM/A stations to the steel pipe network. The temperature of the gas entering the RM/A stations is between 10-13 °C in winter times when the consumption is the largest. The average inlet pressure is about 60 bars. At RM/A station the pressure is reduced to 22 bars which is the design pressure of the network at the starting point of the steel line. The pressure reduction is about 38 bars, which would correspond to a decrease in temperature of approximately 19 °C due to the Joule-Thomson effect. Without any heating, the gas temperature would be negative which could lead to hydrate formation, condensation, and thus equipment error. Therefore, the gas is heated before pressure reduction to compensate for the temperature reduction and the gas leaves the RM/A stations at a temperature of around 8-10 °C. The heating is accomplished through natural gas-burning heaters. Consequently, some portion; around % 0.1 of the received gas is consumed for heating purposes. This consumption could be minimized provided that a lower RM/A outlet temperature could be employed, however, there are no scientific studies or regulations that would help to determine or dictate these outlet temperatures. The practice is based on experience rather than regulations. This study provides preliminary work for determining an optimum RMS/A outlet temperature that would minimize natural gas consumption while mitigating problems associated with low gas temperatures.

This study aims to deliver a framework as well as a road map for determining optimum temperatures at RMS/A outlet, reducing both gas consumption for heating and CO2 emissions associated. Eventually, this framework is going to provide the logical core for a smart heating system that would decide the outlet temperature dynamically through various key inputs obtained in real time through the SCADA system.