The invention entitled "A Grinding System and Method and A Related Ceramic Production Method", of which Hasan Ergin is among the inventors who were received an Investigated Patent Certificate by the Turkish Patent and Trademark Office.

It is an output of the Tübitak project titled "Development of New Grinding Technologies for the Ceramics Industry - Efficient Grinding Technology" carried out in collaboration with Prof. Dr. Hasan Ergin, Kaleseramik Çanakkale Kalebodur Seramik Sanayi A.Ş. and Remas Makine Reduktor Sanayi A.Ş. The aforementioned project it was deemed worthy of the first prize in the research and development category, where 468 projects from all fields were evaluated in the "2021 Productivity Project Awards" competition organized by the T.C. Ministry of Industry and Technology, General Directorate of Strategic Research and Efficiency.

Patent:

Registration Number: 2019 04225 Registration Date: 21/12/2022

Protection Type : Patent

Title of Invention:

A GRINDING SYSTEM AND METHOD AND A RELATED CERAMIC PRODUCTION METHOD

Inventors:

Hasan Ergin, Istanbul Technical University

Ali Altıntaş, Kagan Kayacı, Hatice Turgut, M. Uğur Taşkıran, Ahmet A. Pilevne, Kaleseramik A.Ş.

Subject of Patent:

With the invention, which is the subject of a patent, a new system has been developed for the body mud preparation process by using different raw materials, which is one of the most important stages of ceramic tile production. With the invention, the following technical and economic advantages are provided in the ceramic production process:

• With the new system developed and patented, it was ensured that ceramic clays were produced in a targeted narrower size range and homogeneously (RRSB= d' and n parameters).

• With the developed system, significant savings were achieved in energy consumption. The grinding energy value, which is 36 kWh/ton on average in the existing systems, has been reduced to 19 kWh/ton in the new system; advantages were achieved in terms of both energy saving and sustainability.

• A significant reduction (35%) was achieved in the maintenance and operating costs of the systems.

• In view of its positive effects on the following ceramic production process, 8-10°C reductions were achieved in the firing temperatures of ceramic kilns. Considering the kiln speed and the reduced total firing time, a capacity increase of around 15% and savings in natural gas consumption are achieved.

• The firing behavior of the mass prepared in the new system is much more homogeneous and its melting point is stabilized at 1176-1178 C. The fluctuation in the range of 1180 – 1262 C has been eliminated in the existing systems, and this provides important technical and economic advantages by eliminating the different problems caused by the final product size and firing differences.

Summary of the Invention:

The invention consists of at least one, which is connected in series with each other via mill inlets (2.a) and mill outlets (2.b), rotates around a rotation axis (A) and is configured to transfer the material they grind from one to another in a flow direction (FD). two continuous mills (2), balls (B) in the amount and size that can move with the rotation of the mill (2) around the rotation axis (A) in the inner volume of the mills (2), to feed the material to be grinded to the first mill (2) in the flow direction (F). It relates to a grinding system characterized in that it contains a feed tank (1) connected to the mill and the diameter of a mill (2) in the downstream (FD) direction is larger than the diameter of another mill (2) in the downstream (FD) direction.

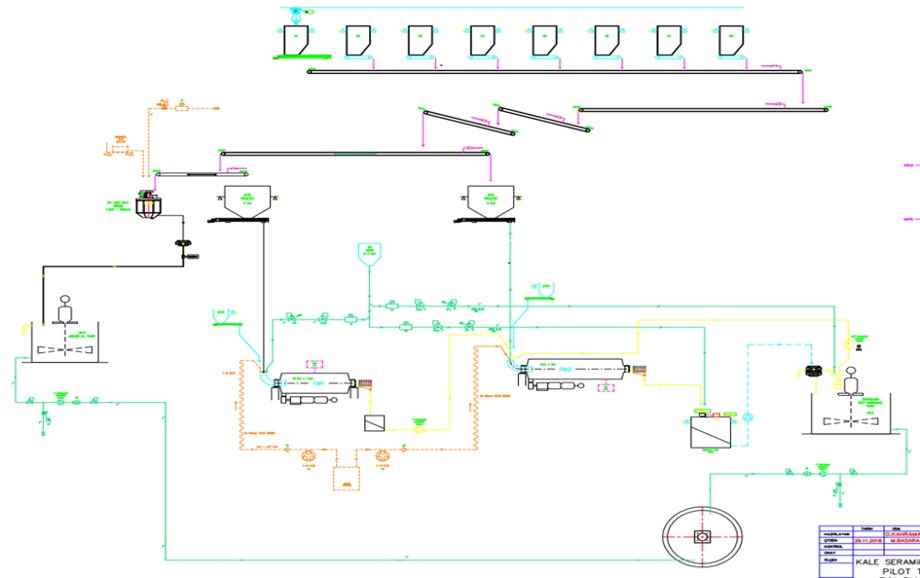

Flow chart of the patented system

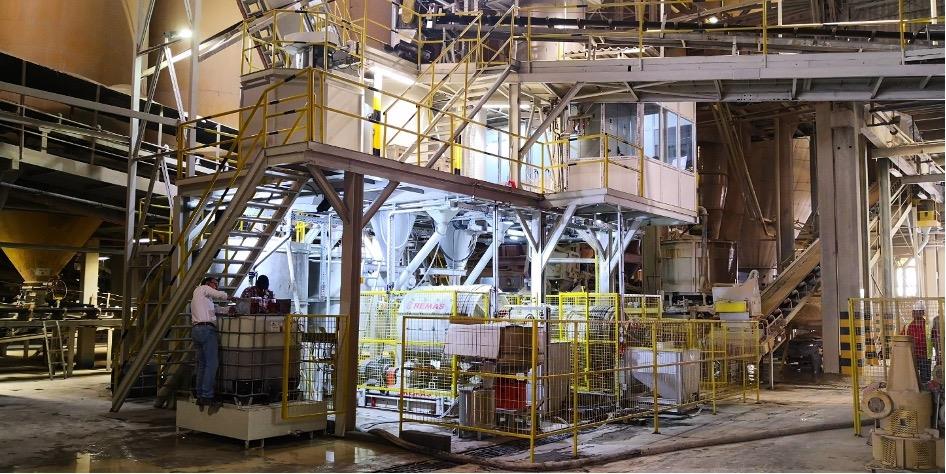

Pilot plant image of the patented system