by

Halide Nur Dursun | Jul 09, 2025

A recent study led by researchers from the Department of Mineral Processing Engineering, in collaboration with the Department of Metallurgical and Materials Engineering, presents an efficient and environmentally conscious method for recovering valuable metals from end-of-life lithium-ion batteries (LiBs). The research team includes Emircan Uysal, Halide Nur Dursun, Dr. Faruk Kaya, Prof. Dr. Fırat Burat, and Prof. Dr. Sebahattin Gürmen.

A recent study led by researchers from the Department of Mineral Processing Engineering, in collaboration with the Department of Metallurgical and Materials Engineering, presents an efficient and environmentally conscious method for recovering valuable metals from end-of-life lithium-ion batteries (LiBs). The research team includes Halide Nur Dursun and Prof. Dr. Fırat Burat from Mineral Processing, and Emircan Uysal, Dr. Faruk Kaya, and Prof. Dr. Sebahattin Gürmen from Metallurgical and Materials Engineering.

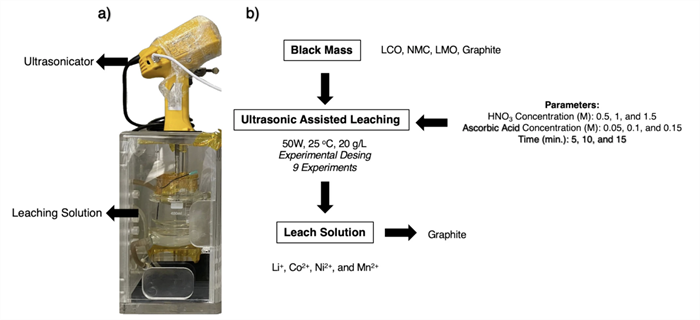

In this study, the researchers targeted the recovery of critical metals from “black mass,” a residue obtained from spent LiBs containing approximately 40% graphite and cathode materials such as LCO, NMC, and LMO. Using an ultrasonic-assisted leaching process with nitric acid (HNO₃) and ascorbic acid (AA), the method achieved over 98% dissolution efficiency for Li, Co, Ni, and Mn under optimized conditions (0.5 M HNO₃, 0.1 M AA, 15 minutes).

The synergy between AA and HNO₃ where AA acts as both a reducing and complexing agent was a key factor in the process’s success. Parameters were optimized using the Taguchi design method and analyzed statistically via ANOVA, resulting in low reagent consumption and a short process time, making the method potentially suitable for industrial applications.

This collaborative effort stands as an example of how interdisciplinary research can offer practical solutions to modern environmental and material supply challenges. By combining expertise in hydrometallurgy and process engineering, the study contributes to the global effort to establish sustainable technologies for critical metal recovery and battery recycling.

Relevant Citation: Uysal, E., Dursun, H. N., Kaya, F., Burat, F., & Gürmen, S. (2025). Recycling of EoL Batteries with Ultrasonic Assisted Nitric-Ascorbic Acid Leaching: Experimental Design and Process Optimization. Mining, Metallurgy & Exploration, 1-11. doi.org/10.1007/s42461-025-01279-0

Experimental set-up (a), and process flow-chart (b)